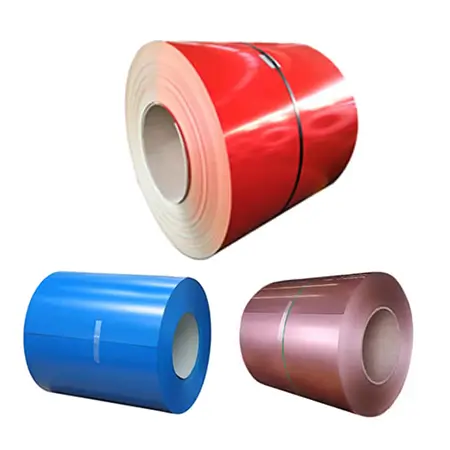

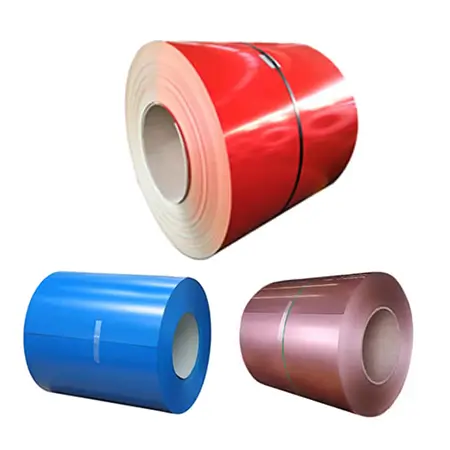

Product details

Color coated sheet, known as color coated steel, is a composite material made by coating one or more layers of organic paint on the surface of a metal substrate (usually galvanized or aluminum zinc-plated sheet) and curing it after baking. Because of its rich color, excellent performance, easy processing and other characteristics, color coated sheet has a wide range of applications in construction, home appliances, furniture, transportation vehicles, advertising signs and other fields.

Main features

Corrosion resistance: the color coating effectively isolates the metal substrate from contact with external corrosive media and improves the corrosion resistance.

Decorative: the coating has various colors and smooth surface, which has good visual effect and decorative.

Processability: the color coated sheet can be processed by shearing, bending, rolling, etc., which is suitable for various architectural and industrial designs.

Environmental friendliness: A dense protective layer is formed after curing of the coating, which reduces the loss of materials and maintenance costs.

Energy-saving: Some of the color coated sheet products have thermal insulation and heat preservation effects, which help to save energy and reduce consumption.

Production process

The production process of color coated sheet mainly includes the following:

Pre-treatment: including cleaning, chemical treatment, electrophoresis, etc. to remove grease, rust and dirt from the surface of the steel plate and enhance the adhesion of the coating.

Coating: evenly coating the surface of the pre-treated steel plate by roller coating, spraying and other methods.

Baking and curing: The coated steel plate is sent to the baking oven, where the coating is cured at high temperature to form a stable coating.

Classification of Coatings

Polyester (PE) coatings: good adhesion and processability, relatively low cost.

Silicone Modified Polyester (SMP) Coatings: Better durability and weatherability than ordinary polyester coatings.

Highly durable polyester (HDP) coatings: excellent weathering, UV and high temperature resistance.

Fluorocarbon (PVDF) coatings: excellent weathering and chemical resistance for harsh environments.

Areas of application

Construction industry: used for roofing, walling, heat-insulating materials, etc.

Home appliance industry: used in the shell of refrigerators, washing machines, air conditioners and other home appliances.

Furniture industry: used for cabinets, bookshelves, office furniture, etc.

Transportation: used in car body, train carriages, containers, etc.

Advertising and signage: used for outdoor billboards, signage, etc.

Precautions

Storage: It should be stored in a dry and ventilated environment, avoiding direct sunlight and rain.

Transportation: Be careful and light during transportation to avoid damage to the coating.

Processing: Avoid sharp tools scratching the coating during processing.

Color coated sheet has become one of the indispensable materials in modern architectural and industrial design due to its beautiful, practical and environmentally friendly characteristics. With the progress of technology and market demand, the product range and application scope of color coated sheet are also expanding.